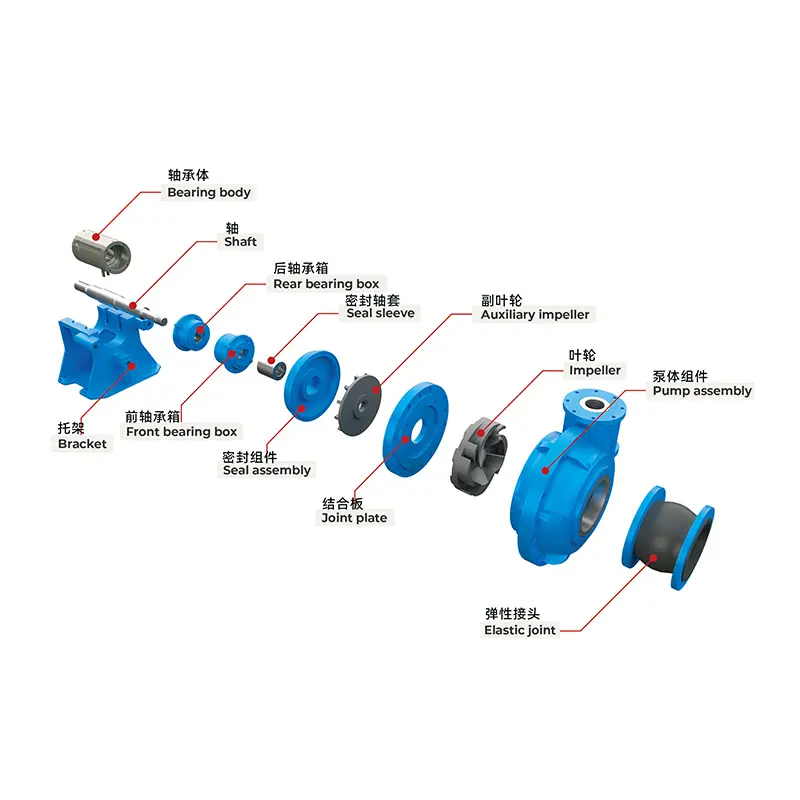

TZJK-TD series ceramic slurry pump

Application industry

★ Metal ore (gold, silver, copper, iron, lead, zinc, tin, molybdenum ore, etc.) processing slurry feed and various concentrates, tailing and the transportation of various materials ;

★ Non-metallic ore (such as phosphorus ore) processing slurry feed and various concentrates, tailing and the transportation of various materials ;

★ The transportation of various abrasive slurry including non-ferrous smelting, sand and gravel aggregate, etc.

Main features

★ The flow-through parts are made of wear-resistant ceramic material, which has a wear resistance more than 3 times that of high-chromium wear-resistant alloy and a hardness of up to 9 on the Mohs hardness, second only to diamond;

★ The pump impeller is designed in cooperation with well-known domestic colleges and universities, using the world's most advanced Solid-Liquid Two-Phase Flow velocity ratio theory, which is very efficient;

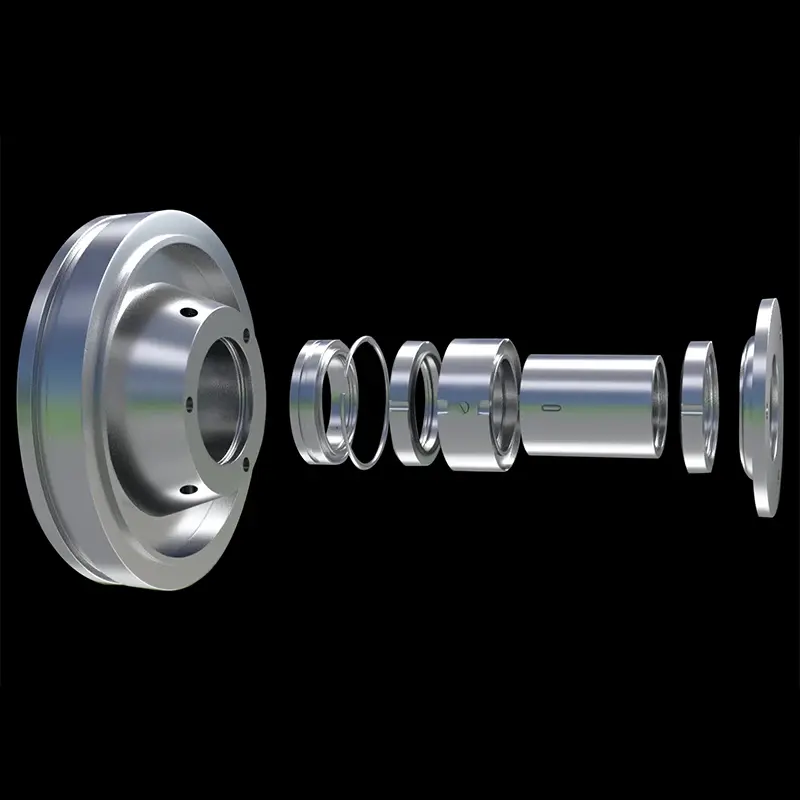

★ The shaft seal can use the our unique "self-circulating cooling mechanical seal" patent technology, which has no packing, no leakage and does not need maintenance. Another shaft seal way is using auxiliary impeller with a combination of packing seal.

★ The high hardness of ceramic flow-through parts is not affected by the damage of cavitation and has long service life;

★ Ceramic flow-through parts wear slowly, which can reduce the fluid loss of the pump and save energy.

★ New integrated pump casing design, simple structure, greatly reducing maintenance time.

Parameters and working conditions for the Pump

Flow rate: 50-4000m³ / h;

Head: 10-100m;

The maximum diameter of the particle should be less than 4mm;

The slurry temperature allowed is less than 85 ° C.

Product Display