Specialized Ceramic Slurry Pump - High Wear-Resistance Pumping Solution for Abrasive and Corrosive Slurries

Key Features & Technical Advantages

✅ Ceramic-Lined Flow Parts

Wetted parts including the impeller, volute, and wear plates are made from sintered alumina or silicon carbide ceramic, extending service life 5–10 times longer than metal pumps.

✅ Exceptional Wear & Corrosion Resistance

Suitable for highly abrasive and corrosive slurries, such as zirconium oxide, aluminum oxide, silicon nitride, kaolin, or glaze slurry.

✅ High-Efficiency Hydraulic Design

CFD-optimized impeller design ensures high flow rates and reduced turbulence-induced wear.

✅ Low Maintenance Downtime

Fewer replacement cycles and longer intervals between overhauls result in lower operating costs.

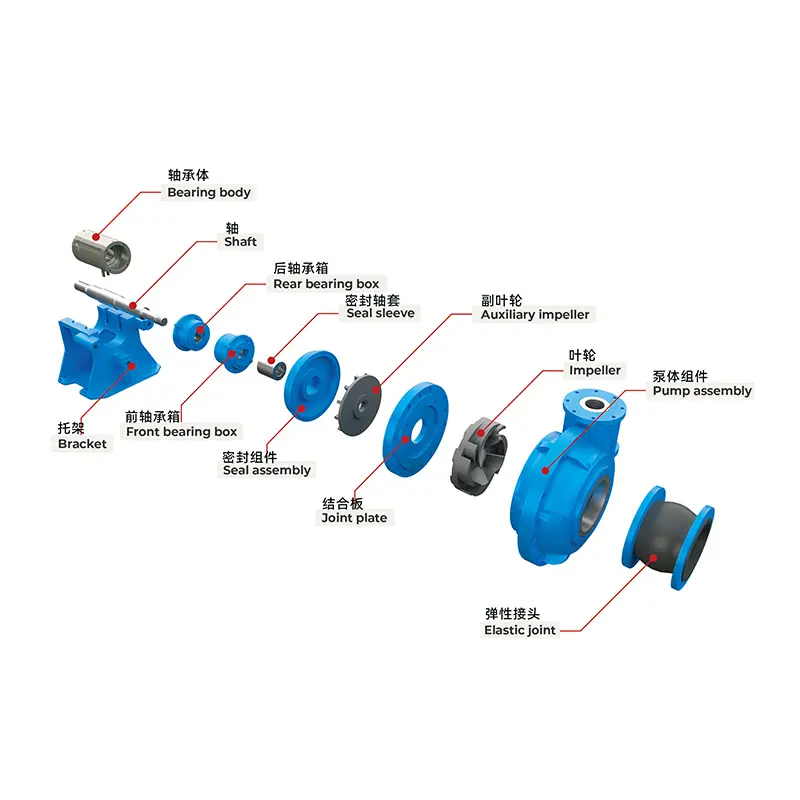

✅ Modular Construction

Easy access for inspection and part replacement; compatible with standard pump interfaces.

Technical Specifications

| Parameter | Value |

| Flow Capacity | 3 – 150 m³/h |

| Delivery Head | 10 – 70 meters |

| Operating Pressure | Up to 1.6 MPa |

| Slurry Concentration | Up to 75% solids by weight |

| Particle Size Handling | ≤ 5 mm |

| Ceramic Materials | Alumina (Al₂O₃), SiC, ZTA |

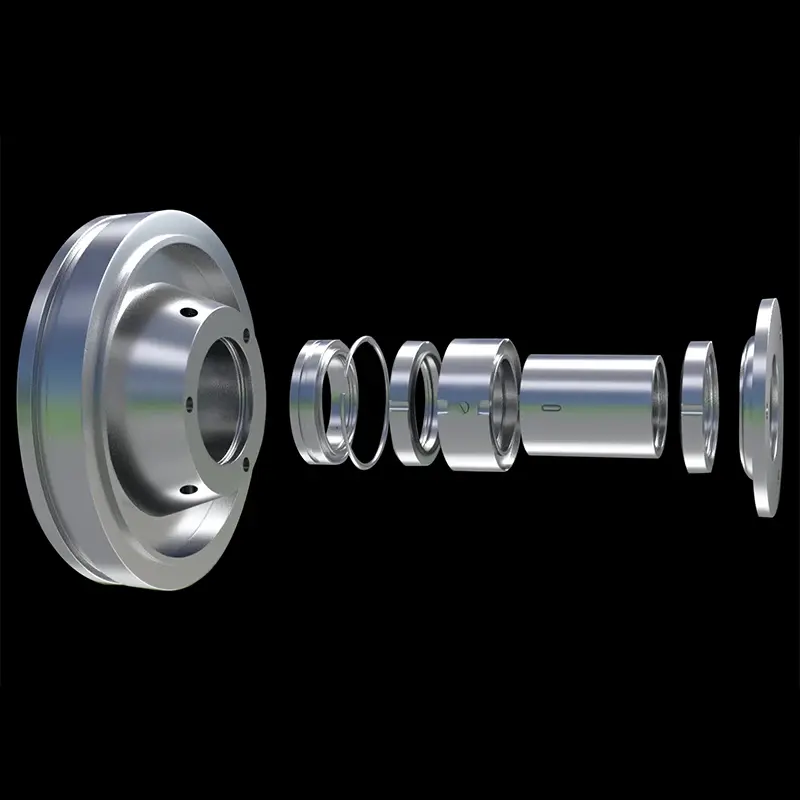

| Seal Options | Mechanical seal, packing seal |

Typical Applications

Ceramic Manufacturing

Transport of zirconia, alumina, kaolin, or glaze slurries in precision ceramic part production.

Battery Materials & Electronics

Safe and clean pumping of lithium battery cathode/anode slurry, ceramic dielectric slurries.

Mining and Minerals

Suitable for mineral slurry containing silicon-based abrasives or chemical reagents.

Fine Chemical & Catalyst Industry

Precise dosing and circulation of nano-powder slurries or catalyst suspensions.

Environmental & Waste Treatment

Handling of abrasive industrial sludge or corrosive tailing liquids.

Product Display