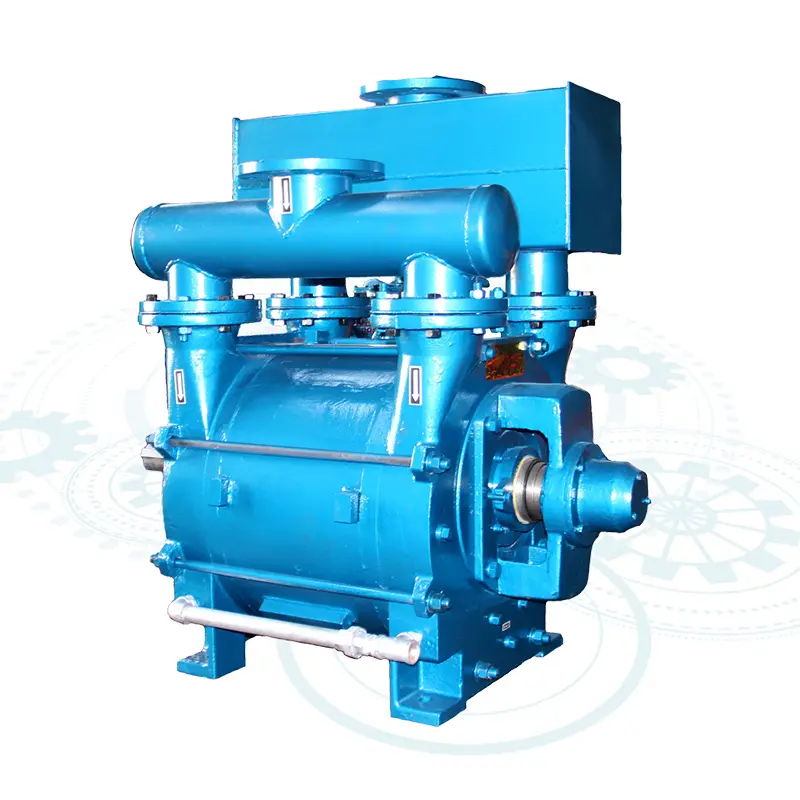

LRA (C) series water ring vacuum pump

Main features

1. By improving the design of blade inclination angle, front and rear disk suction and exhaust port size, radial clearance between impeller and pump body, i.e. radial ratio, the air volume is increased by 5% compared with the same model on the market.

2. Machining centers and other high-precision numerical control equipment are used to process the pump cover and other key parts, resulting in stable performance and reliable operation.

3. Impeller materials are all made of ball-mill cast iron casting or steel plate welding, which fully guarantee the stability of the vacuum pump impeller under all kinds of bad working conditions and greatly improve the service life of the vacuum pump.

4. Vacuum pump shaft sleeve is made of wear-resistant stainless steel, which greatly improves the service life than ordinary materials.

5. Pulley(belt drive) adopts standard high-precision taper sleeve pulley, which is reliable in operation, and adopts imported belt, which has a long service life and is easy to dismantle.

6. Coupling(direct coupling transmission) adopts standard high-precision elastic coupling, the elastic element is made of rubber, stable and reliable operation, long service life.

7. Sealing adopts packing seal or mechanical seal, which can meet the requirements of different working conditions.

8. The unique top-mounted separator of water ring pump saves space and effectively reduces noise.

9. The water ring vacuum pump has inspection ports on both sides, which is convenient for checking the gap, corrosion and scale accumulation.

Main technical indexes

| Ultimate vacuum | 160hPa (-85kPa) or 33hPa (-98kPa) |

| Flow rate | 5.8~646m³/min |

| Shaft power | 8.4~808kW |