Ceramic Slurry Pump (TZJK-TD Series) – Advanced Wear Resistance for Extreme Conditions

Key Features of the Ceramic Slurry Pump

✅ Ultra-Wear-Resistant Ceramic Construction

Flow components (impeller, casing, liner) are made from advanced industrial ceramics with a Mohs hardness rating of up to 9—second only to diamond.

Wear resistance is over 3 times higher than that of high-chrome alloys, significantly reducing replacement frequency and operating costs.

✅ Extended Lifespan & Lower Total Cost of Ownership

Slower wear rates improve pump efficiency and reduce energy loss due to internal erosion.

Fewer maintenance shutdowns and lower parts replacement costs deliver long-term savings.

✅ Cavitation-Proof Performance

Ceramic materials withstand the effects of cavitation and corrosive particles, ensuring stable performance in aggressive media.

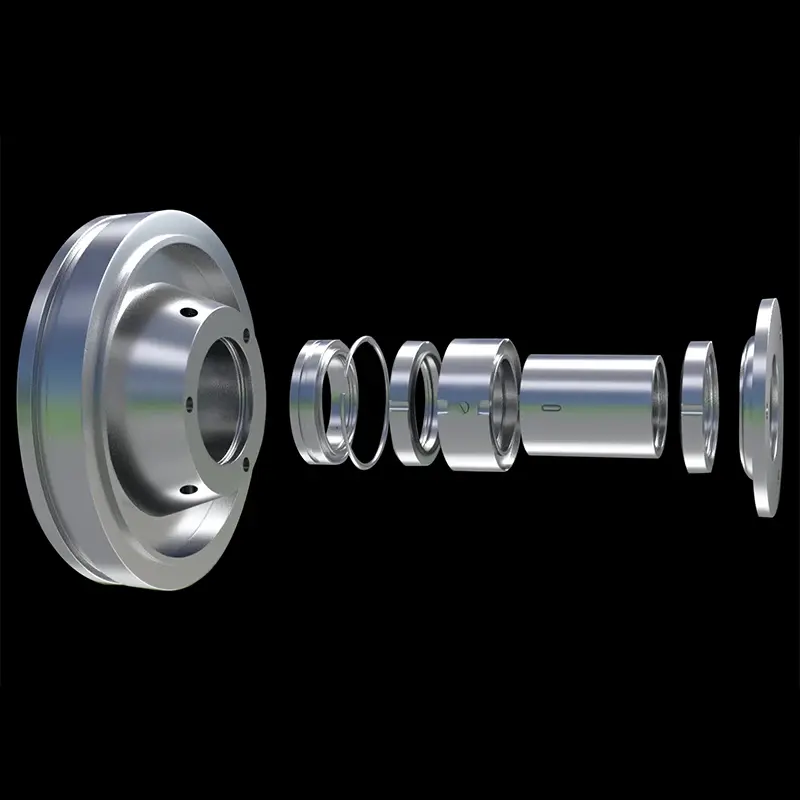

✅ Patented Zero-Leakage Shaft Seal Technology

Choose from two seal options:

Self-circulating cooling mechanical seal (patented) – No leakage, no packing, no maintenance required.

Traditional auxiliary impeller + packing seal – Reliable and cost-effective.

✅ High-Efficiency Impeller Design

Developed in collaboration with top Chinese universities, using the Solid-Liquid Two-Phase Flow Velocity Ratio Theory, optimizing hydraulic performance for energy-efficient slurry transport.

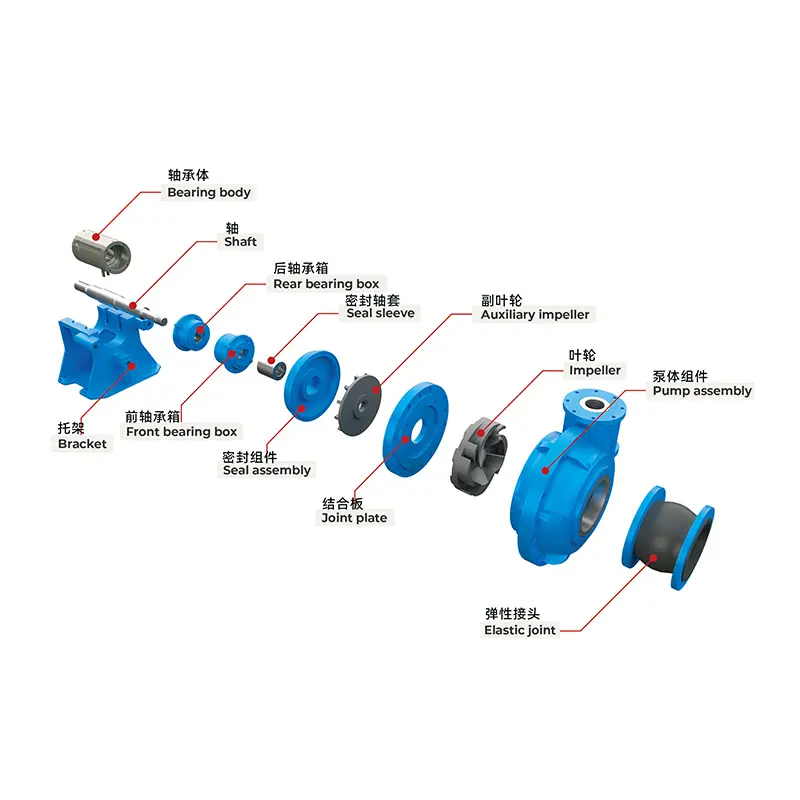

✅ Simplified Integrated Pump Casing

Modular, integrated pump housing minimizes maintenance time and simplifies disassembly, even in remote or rugged job sites.

Application Industries

The TZJK-TD Ceramic Slurry Pump is engineered for some of the toughest slurry-handling applications, including:

🔹 Metallic Ore Processing

Suitable for transporting feed slurries, concentrates, tailings, and abrasive sludges in gold, copper, iron, zinc, tin, molybdenum, lead, and silver ore processing.

🔹 Non-Metallic Ore Processing

Ideal for handling slurry, tailings, and feed in phosphate, limestone, or kaolin operations.

🔹 Smelting and Foundries

Effective in transporting abrasive and corrosive fluids in non-ferrous metal refining.

🔹 Aggregate and Sand

Handles highly abrasive mixtures in sand, gravel, and aggregate processing plants.

Technical Specifications

| Parameter | Value |

| Flow Rate | 50–4000 m³/h |

| Head | 10–100 m |

| Max Particle Size | ≤ 4 mm |

| Max Slurry Temperature | ≤ 85°C |

Built for Global Industry Standards

With its blend of patented technologies, top-tier ceramic materials, and innovative hydraulic design, the TZJK-TD Ceramic Slurry Pump represents the future of industrial slurry pumping. Whether you're upgrading from high-chrome alloy pumps or seeking longer-lasting performance in extreme conditions, this pump is engineered to help you reduce downtime, lower costs, and boost productivity.

Product Display