Leave Your Message

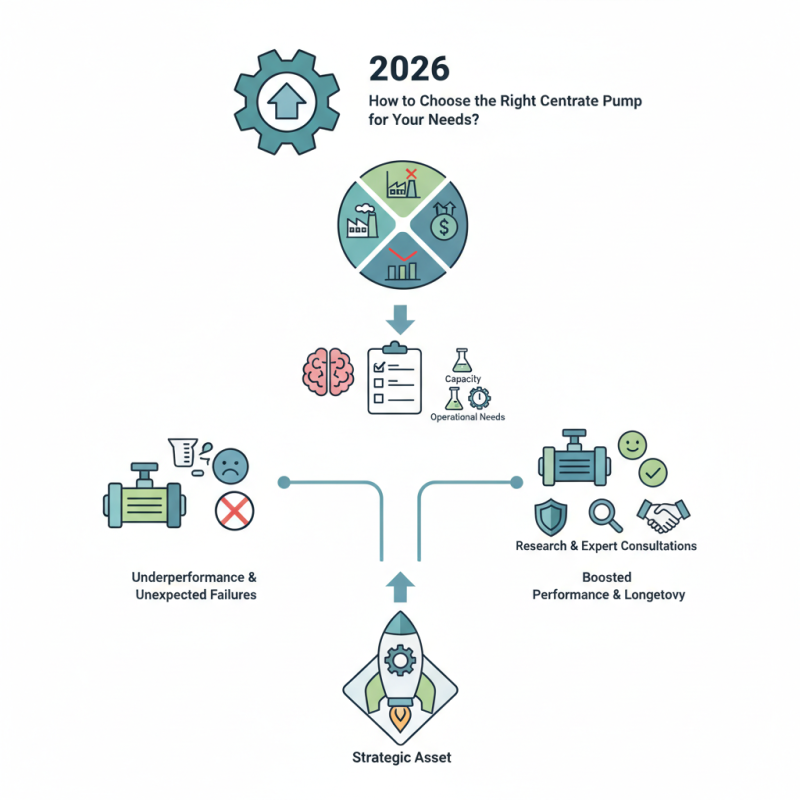

In the fast-evolving industrial landscape, selecting the right Centrate Pump is crucial. Industry reports indicate that poor pump choices can lead to reduced efficiency and increased operational costs. For instance, the 2022 Pump Industry Analysis highlighted that incorrect pump selection can cost companies up to 20% in energy consumption.

When considering a Centrate Pump, understanding specific operational needs is essential. Different applications require varying capacities and materials. The right pump can enhance productivity and reduce maintenance downtime. However, many organizations do not invest enough time in this decision. This oversight can result in underperformance.

It’s important to blend practical requirements with industry standards. Misguided selections can lead to unexpected failures. Not all pumps are equal, and a thorough evaluation process is key. Research and expert consultations can mitigate risks. Making an informed choice can ultimately boost performance and longevity. The right Centrate Pump is more than just equipment; it's a strategic asset.

Centrate pumps play a crucial role in various industries. These pumps are specifically designed to handle centrate, a liquid byproduct generated during filtration processes. They extract moisture from solid materials while ensuring efficient liquid transfer. Understanding how these pumps work is essential for selecting the right one for your application.

The functionality of a centrate pump revolves around its design. Typically, they feature a strong motor and durable components. This combination allows them to manage varying flow rates and handle different viscosities. However, choosing the wrong pump can lead to inefficiencies. Users may find themselves facing issues such as clogging or inadequate flow.

It’s important to reflect on your unique requirements. Consider the characteristics of the fluid you will pump. The viscosity and temperature affect pump performance significantly. Additionally, evaluate the pump's capacity to ensure it meets your needs. Over time, improper choices could result in costly downtime and maintenance. Understanding how centrate pumps operate is a key step toward making informed decisions.

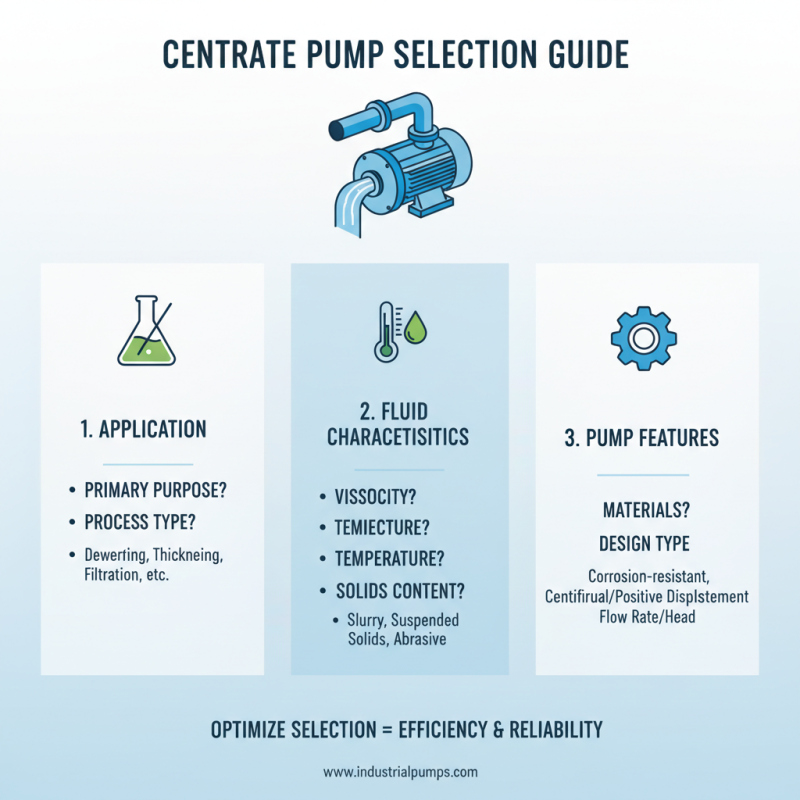

When selecting a centrate pump, consider the application. What is its primary purpose? Different processes require different pump features. Understanding the application will help narrow your choices. Think about fluid characteristics too. Viscosity, temperature, and solids content matter. These factors affect performance.

Next, examine flow rate requirements. How much liquid do you need to move? Too high a flow rate can lead to inefficiency. Conversely, too low can stall operations. Assess your system pressure as well. It needs alignment with the pump’s capability.

Pump materials are crucial also. Ensure they can withstand the environment. Corrosion and wear can lead to failures. Evaluate maintenance needs too. Some pumps require more upkeep than others. Think about long-term costs, not just initial investment. Each choice should reflect a balance between quality and sustainability.

When selecting the right centrate pump, assessing your specific application requirements is crucial. Centrate pumps are widely used in various industries, including wastewater treatment and food processing. According to a recent industry report, the global pump market is expected to grow by 4% annually, reaching a value of over $50 billion by 2026. This growth emphasizes the importance of choosing the correct pump to meet your needs effectively.

Understanding the characteristics of your application is essential. Consider factors like flow rate, viscosity, and temperature. Pumps may require different materials depending on the substances they will handle. For instance, a study highlighted that 30% of pump failures are related to material incompatibility. Ensuring that your pump materials are suitable for the application can prevent costly downtime.

Moreover, evaluating maintenance needs is often overlooked. Pumps require regular maintenance, and some designs are easier to service than others. The complexity can lead to increased operational costs. Industry data suggests that maintenance can account for up to 15% of total operational expenses. Make sure to balance initial costs with long-term reliability and serviceability in mind.

| Application | Flow Rate (GPM) | Pump Type | Material | Power Source |

|---|---|---|---|---|

| Oil & Gas | 50 | Centrifugal | Stainless Steel | Electric |

| Wastewater Treatment | 80 | Submersible | Polypropylene | Hydraulic |

| Mining | 100 | Gear | Cast Iron | Diesel |

| Food & Beverage | 30 | Positive Displacement | Food Grade Plastic | Electric |

Choosing the right centrate pump involves understanding different types available. Centrate pumps vary widely in efficiency, flow rate, and applications. Data suggests that screw pumps often outperform others in handling abrasive materials. They are commonly used in industrial settings. Their ability to minimize wear makes them valuable. They require careful monitoring for maintenance purposes.

Diaphragm pumps are another option. They excel in applications demanding a precise flow rate. Their reliability in transferring corrosive fluids is noteworthy. However, they may not handle viscous materials efficiently. A recent report indicated that around 30% of applications face challenges when using diaphragm pumps with thicker slurries.

Centrifugal pumps are popular for their simplicity. They perform well with low-viscosity liquids. However, they can struggle with high solids content. About 25% of users in a recent survey expressed dissatisfaction with their performance in these scenarios. Understanding these limitations is crucial. Evaluating your specific requirements can lead to better choices in pump selection.

Choosing the right centrate pump involves budgeting and maintenance considerations. According to industry reports, maintenance costs can consume up to 20% of the total operating budget over a pump's lifetime. Regular maintenance prevents costly breakdowns. It is crucial to track performance and wear over time.

Tips: Schedule routine inspections. Remember, small issues can become major problems.

A proper budget should include not just initial costs but also ongoing expenses. Operating a centrate pump can also incur energy costs, which are often overlooked. According to estimates, energy costs may account for 40% of total lifecycle costs. Reviewing energy efficiency is vital.

Tips: Ask about energy usage before purchasing. Understand your long-term expenses.

Be prepared for fluctuations in operation. Demand can vary, as can the quality of materials being processed. This uncertainty can impact maintenance needs significantly. Sometimes, maintenance schedules need adjustments based on performance data. Flexibility in your approach can lead to better outcomes in the long run.

Tips: Keep a maintenance log. It can reveal patterns that aid in planning.