Leave Your Message

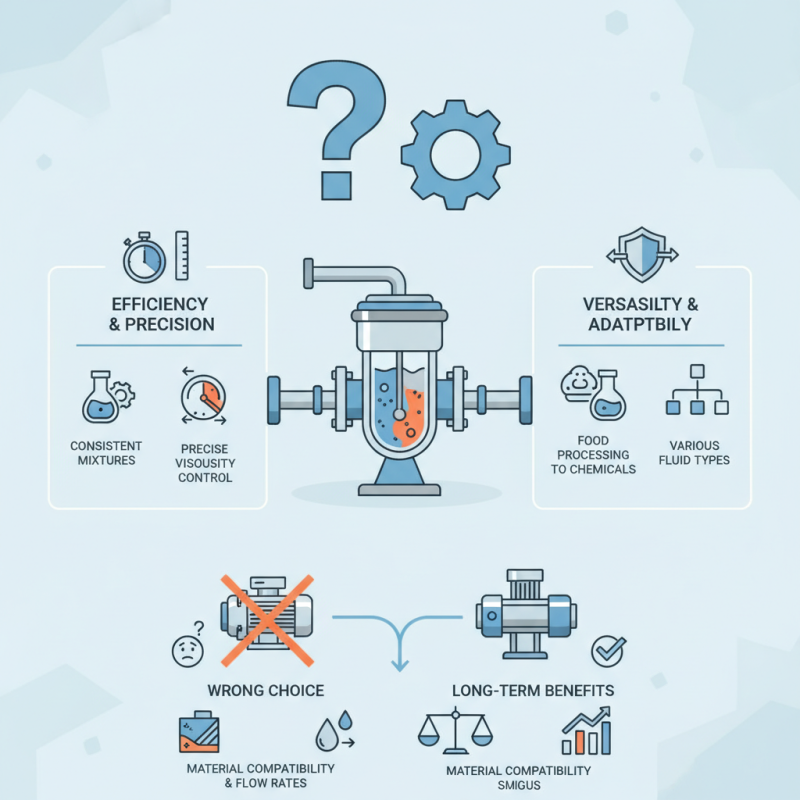

In industrial settings, efficiency and precision are paramount. Choosing the right equipment can significantly impact productivity. A Mixing Pump stands out in this context. It offers unique advantages for blending materials.

Mixing Pumps are designed to handle various types of fluids. They ensure consistent mixtures, which is crucial in many applications. With precise control over viscosity, businesses can achieve desired results more reliably. The versatility of a Mixing Pump allows it to address specific needs across industries, from food processing to chemicals.

However, not all Mixing Pumps are created equal. Some may struggle with certain fluid types. Users should reflect on their requirements before making a decision. It is important to consider factors such as material compatibility and flow rates. Investing time in selecting the right Mixing Pump can lead to long-term benefits and enhanced operational efficiency.

Mixing pumps play a crucial role in various industrial applications. They ensure thorough mixing of materials, which is vital for product consistency. According to a report by the National Institute of Standards and Technology, well-mixed components can enhance product quality by up to 25%. This boost in efficiency can lead to significant cost savings and improved production rates.

One significant advantage of mixing pumps is their versatility. They can handle both viscous and low-viscosity fluids. This adaptability makes them suitable for industries like food and beverage, pharmaceuticals, and chemicals. For instance, a large-scale study revealed that companies using mixing pumps reported a 30% reduction in processing time. However, it's essential to choose the right pump type. Misalignment in pump selection can lead to inefficient mixing.

Additionally, some operators face challenges with maintenance. Regular upkeep is necessary for optimal performance. Industry data suggests that neglecting maintenance can decrease efficiency by up to 15%. Pumps may require calibration and inspection, which can be time-consuming but crucial for sustained operation. Investing in a reliable mixing pump can yield substantial long-term benefits, but ongoing attention is key.

| Feature | Description | Benefits |

|---|---|---|

| Efficient Mixing | Mixing pumps provide thorough and consistent mixing of various materials. | Improves product quality and consistency. |

| Versatility | Suitable for a wide range of liquids, including corrosive and viscous substances. | Enhances operational flexibility. |

| Energy Efficiency | Designed to use less energy while maintaining performance. | Reduces operational costs. |

| Durability | Constructed from robust materials to withstand harsh environments. | Ensures long-term reliability and reduces downtime. |

| Adjustable Speed | Ability to modify the mixing speed according to the application needs. | Provides precise control over mixing processes. |

Mixing pumps play a vital role in various industries. They are essential for blending and transporting fluids with different viscosities. Several types of mixing pumps cater to these diverse industrial needs. For instance, centrifugal mixing pumps are widely used in the chemical sector. They efficiently handle low-viscosity liquids and provide a steady flow. Their design allows for easy maintenance, but they may struggle with thicker substances.

In the food industry, positive displacement pumps are often preferred. They ensure precise measurements and gentle handling of ingredients. These pumps can manage both solids and liquids without damaging the product. However, they might require more frequent cleaning to maintain hygiene standards. Moreover, some operators find it challenging to calibrate them accurately.

Another option is the magnetic-drive pump. This type minimizes leakage, making it suitable for hazardous materials. They are compact and quiet, which is a plus for many facilities. Nonetheless, their initial cost can be higher, leading some companies to hesitate. Each type of pump has its strengths and weaknesses. Choosing the right one can significantly impact efficiency and productivity in an industrial setting.

Mixing pumps are essential in various industries. They ensure consistent blending of fluids and materials. When selecting a mixing pump, there are several key features to consider.

The pump's capacity is crucial. Studies estimate that the right capacity can improve efficiency by up to 30%. A pump that suits your output needs prevents bottlenecks. It's also essential to assess viscosity levels. High-viscosity materials can strain performance if the pump isn't adequately rated.

Material compatibility is another critical factor. Many industries require pumps that can handle corrosive or abrasive substances. Reports highlight that using unsuitable materials can lead to premature wear. This aspect often goes unexamined – resulting in costly maintenance. Pump design should also be considered. Compact designs can save space but may compromise on power. Finding the right balance between size and performance is often a challenge.

Mixing pumps play a crucial role in various industrial processes. To ensure optimal performance, regular maintenance is essential. According to a recent industry report, nearly 40% of mixing pump failures are due to improper maintenance practices. This highlights the need for a proactive approach.

One key maintenance tip is to regularly inspect seals and gaskets. These components often wear out, leading to leaks. Timely replacements can save significant costs. Additionally, monitoring the pump's temperature is vital. Operating above recommended levels can reduce its lifespan. Regularly checking for unusual noises can also indicate underlying issues.

Another aspect to consider is the pump's alignment. Misalignment can lead to increased wear on bearings and other parts. In fact, misaligned pumps can consume up to 25% more energy. Keeping an eye on performance metrics is beneficial. Small inefficiencies can often result in larger problems down the line. Addressing minor issues early can provide substantial long-term savings.

Mixing pumps are essential in various industries for seamless operation. They help blend different substances efficiently. Their cost-effectiveness stands out, especially when considering long-term operations. An initial investment may seem high, but the savings accumulate over time.

Mixing pumps reduce downtime. They provide consistent mixing, minimizing wasted materials. This efficiency allows companies to meet production demands, keeping costs low. However, it’s vital to assess maintenance needs regularly. Operating a mixing pump without adequate attention can lead to higher repair bills.

**Tips:** Always check fluid viscosity for optimal pump performance. Scheduling routine maintenance can extend pump life. Investing in training for operators can prevent mishaps and ensure proper use. Understanding how to troubleshoot minor issues can help reduce unexpected expenses.