Air Foil Bearing Turbo Blower – Oil-Free, High-Efficiency, and Maintenance-Free Aeration Solution

Key Features of Air Foil Bearing Turbo Blower

✅ Air Foil Bearings = No Oil, No Touch, No Wear

The blower uses air foil bearings that rely on a cushion of air for rotation—completely eliminating the need for lubricants or mechanical contact. This results in zero friction, zero maintenance, and a long service life.

✅ High-Speed Permanent Magnet Motor

Drives the impeller directly with speeds up to 20,000 RPM, delivering high efficiency and compact design with no gearbox or belts.

✅ Integrated VFD + PLC Control System

Offers real-time performance monitoring, automatic load adjustment, and remote control capability, reducing manual operation.

✅ Ultra-Low Noise and Vibration

Operates at <80 dB(A) with minimal vibration, ideal for indoor and urban settings.

✅ 100% Oil-Free Air

Ensures clean, dry, and oil-free airflow—perfect for sensitive applications like biological aeration, pharmaceuticals, or semiconductors.

Technical Specifications

| Parameter | Value |

| Flow Rate | 5 – 300 m³/min |

| Pressure Rise | 40 – 100 kPa |

| Motor Type | High-speed PMSM |

| Bearing Type | Air foil bearing (oil-free) |

| Cooling | Air-cooled or water-cooled options |

| Noise Level | < 80 dB(A) |

| Power Range | 15 – 300 kW |

| Control | Touch screen PLC + VFD, remote compatible |

Applications of Air Foil Bearing Turbo Blower

This advanced turbo blower is ideal for:

🏭 Wastewater Treatment Plants (WWTPs)

Biological aeration tanks, MBR systems, SBR, oxidation ditches

🌾 Food & Beverage and Pharmaceutical Industry

Clean air requirements without oil contamination risk

🧪 Chemical & Semiconductor Manufacturing

Precise, stable airflow with zero lubrication concerns

🎐 Textile & Paper Mills

Used for air knife drying, conveying, and oxidation processes

🏢 Building HVAC and Cleanroom Pressurization

Quiet and vibration-free operation for sensitive environments

Why Choose Air Foil Turbo Blowers?

✓ 30–40% energy savings vs traditional blowers

✓ No need for oil changes, seals, or bearing replacement

✓ Reduced carbon emissions and noise pollution

✓ Long-term operational stability with minimal intervention

✓ Future of industrial air delivery is here — oil-free, quiet, efficient, smart..

Contact us for datasheets, 3D models, and on-site evaluations

We offer full support for system integration, energy audit, and ROI analysis.

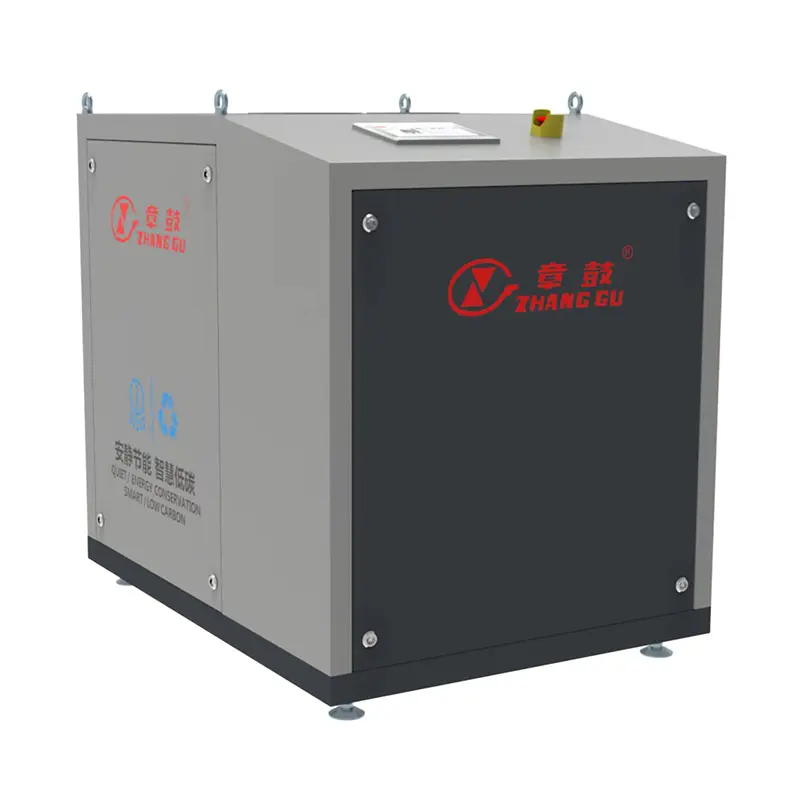

Product Display